3. thermoplastic elastomer (TPE, TRP). Porous material with visible pores and a deep profile.

- Special materials for the sole.

- How do I choose the sole material when buying shoes?

- Speaking of rubber.

- What are the most reliable methods of protecting shoe soles and how to check their quality?

- Leather or synthetic?

- Outsole of a trekking boot

- Do I need heel prophylaxis?

- Peculiarities of teaching technique related to the implementation of FSES

- Technology: Learning theory and methods in an educational institution

- conquered

- See what 'underbelly' means in other dictionaries:

- SUMMARY

- See what 'sledgehammer' means in other dictionaries:

- Craft material with patterns

- Method of attaching the sole

- Thermoplastic Rubber (TPR)

- construction of shoes

- The outer parts of a shoe upper

- Disadvantages of textile shoes

Special materials for the sole.

Which composition is the best for everyday shoes? Which is the best for cold days? Shoe manufacturers choose the material depending on the purpose and conditions of use. There are several types of it. Here is a comparison of the pros and cons of eight types of soles.

1. leather. This sole is considered to be the traditional sole for making shoes. Leather has been used since the time of our ancestors. The technology for creating such shoes has survived to this day, but leather is an expensive material, so it is more often used for expensive shoes and boots.

- It is the best material to enhance the beauty of the product.

- As an environmentally friendly material, it is not harmful to the environment.

- Good hygienic properties and breathability. Suitable for summer shoes.

- Flexible and deformable – cushions when walking and is easy on the joints and spine.

The best material reveals weaknesses on closer inspection.

- High abrasion resistance - leather soles are not suitable for active wear.

- What other disadvantages does leather have? Intolerance to moisture. In rainy weather, leather soles can absorb moisture and deform as they dry.

- Slippery material. Not suitable for winter.

- Expensive to buy. Affects the price of the shoe.

2. combination. Which material combines the advantages of polyurethane (PU) and thermal polyurethane (TPU)? The combination!!! It consists of a bottom layer (TPU) and a PU upper material. This sole has visible layering and texture.

- This material is characterized by its thermal insulation. The porous structure contains air that prevents cold air from entering. This prevents the sole from freezing.

- anti-slip. This is a factor in favor of using composite soles in winter shoe models.

- abrasion resistance. Shoes with a composite sole last a very long time.

- Excellent cushioning properties. It dampens the vibrations when walking and relieves the spine.

How do I choose the sole material when buying shoes?

It is difficult to say which is the best sole material and will suit you best. A lot depends on the time of year, the purpose of the shoe and your preferences.

What should distinguish winter soles? Winter boots should have a good profile - deep and varied to prevent slipping. The best sole material for such boots is rubber, polyvinyl chloride, and combinations thereof.

What should the soles of shoes for the transitional period be like? Here the choice is larger. The best material for spring and fall shoes must have good traction, slip resistance, cushioning and moisture protection.

What are the right soles for summer? Summer soles should be light. Breathable materials that have high hygienic properties are suitable.

How should the sole of sports shoes be made? The sole of a running shoe should be flexible enough not to stiffen the foot and keep it in place. Grip on the ground is also important. Rubber and caoutchouc are suitable for sports shoes.

The sole of the shoe affects its construction, durability and comfort.

It is difficult to say which material is most suitable; a lot depends on the season, the purpose of the shoe and your requirements.

Speaking of rubber.

A method such as compression vulcanization should be mentioned here. A mold is filled with molten rubber and bonded to the substrate, allowing the material to set and form a whole without the need for any particular nuances. Incidentally, almost 30 percent of all bottoms in the world are made precisely from rubber, adding various components. Such popularity is due to the properties of the material and its resistance to various factors.

A combination of different processes is used in the manufacture of special shoes that are exposed to considerable stress. The list of such products usually includes hiking boots, football boots and other similar products. Gluing requires precise control of the process and a perfect fit between the sole and the ground. This is where mistakes and failures often occur: since ideal components are not available in the production warehouses, slightly larger or smaller soles may be used, which later damage the entire product. For guidance on good storage, see our article on storage and components.

Rubber soles work well in any weather

What are the most reliable methods of protecting shoe soles and how to check their quality?

Of course, there is no one ideal. Each model and material requires a different approach. Even combinations do not always lead to the best results. Leather, rubber and fabric all have their own characteristics, so it cannot be said that 'this' method is better than 'that'. But you can and should test the quality of the combination.

Nailing is easy to check - you just need to make sure there are no gaps and that everything is nailed tight. When inspecting the connections, you need to make sure the threads are not broken and that they are strong enough to withstand the friction. The adhesive bond is the most unreliable. Poor workmanship is usually reflected in leaks or swelling. Over time, this develops into a phenomenon known as 'the shoe wants to eat'. If the methods of fastening shoe soles were combined, you should also check whether the dimensions of the bottom and sole coincide, because in this case you will hold in your hands a special model, where reliability should be the most important characteristic.

One might think that this article is only useful for manufacturers or repairers. However, this is not the case. Can't you remember when your sneakers or shoes ever let you down at the most inopportune moment? Knowing the basics about repairs and their types will always help you make the best choice. And remember that nothing lasts forever, but you will definitely be able to buy the best footwear that will outlast you.

Leather or synthetic?

Today's manufacturers use both natural leather and synthetic materials to create trekking boots.

Full-grain leather shoes are rarely used in mass production today. This material is mainly used for heavy trekking boots. The main advantage of these models is the tight fit, which preserves the necessary mobility of the ankle. The natural material acts like a membrane: it enables natural moisture transport and breathability. The performance of these boots largely depends on how the leather is processed.

The main disadvantage of these boots is their weight. They are also more prone to injury from sharp stones. When the shoe dries out and accumulates a critical amount of moisture, it becomes difficult to dry; accelerated drying over the fire can cause shrinkage and deformation of the upper.

Modern synthetic models are more practical. They are undemanding, quick-drying, light, moisture-wicking and air-permeable. The incorporation of elastane, polyester or hard-wearing polyamide and Kevlar threads into the fabric structure makes the shoe upper resistant to cuts and other damage. Potentially vulnerable uppers are usually complemented by abrasion-resistant insoles.

Outsole of a trekking boot

A mountain boot has a reinforced sole with a pronounced profile. Their rigidity and thickness varies according to the class of boot.

In hiking boots and medium-weight trekking boots, the outsole is thinner and more flexible and offers more cushioning. In these shoes, the foot feels the terrain well and has better control when walking. However, they offer comfort and safety on flat trails and moderately steep slopes.

With heavy trekking shoes, the sole is more robust and can be up to 4 cm thick. Flexibility and lightness are sacrificed in favor of more important attributes like stability, off-road mobility and increased foot protection in difficult terrain.

The sole of a professional trekking shoe is made up of several layers, with each layer fulfilling its own function.

sole – the lower layer of rubber, which is in direct contact with the ground and provides the necessary traction. In most modern models, this part is made of vulcanized rubber with improved durability, an optimal balance between rigidity and flexibility, and abrasion resistance. Some manufacturers use modified rubber with inclusions of mineral granules to improve grip, strength and durability.

rigid plate – is a plastic or metal insert that provides additional torsional rigidity, ie better resistance to twisting. Thanks to its special configuration, this element protects the foot from twisting while maintaining the longitudinal flexibility of the sole and a good ride.

Cushioning insole – A cushioning insole is a layer of flexible, vibration-absorbing material that reduces stress on the joints and spine when walking. In professional trekking shoes, this padding has a well thought-out anatomical profile with zones of different densities.

Do I need heel prophylaxis?

No, it is enough to prevent the part of the sole that regularly touches the ground. Of course, the heel also has regular contact with the ground, but prophylaxis is not necessary here. It is only necessary to monitor the wear dynamics of the heel counter and replace it before the heel counter is completely worn out in one part of the heel (otherwise, when another layer of the heel counter wears out, the entire heel counter has to be replaced, which is more expensive than replacing the heel counter). ).

Diligent daily care is the key to the longevity of any shoe. Even the most expensive pair of shoes is no exception.

Peculiarities of teaching technique related to the implementation of FSES

To this discount we can add a discount for your educational institution (depending on how many of your colleagues have completed Inforourock courses).

Additional cumulative discounts (from 2% to 25%) are currently available for 56,360 educational institutions. To find out what discount applies to all employees of your educational institution, log in to your personal Inforourock account.

Technology: Learning theory and methods in an educational institution

To this discount we can add a discount for your educational institution (depending on how many of your colleagues have completed Inforourock courses)

There are currently 56,360 educational institutions receiving cumulative discounts (from 2% to 25%). To find out what discount applies to all employees of your institution, log in to your personal Inforourock account.

conquered

See what 'underbelly' means in other dictionaries:

chug – Cinch … dictionary of usage of the letter Y

SUMMER – Sole (SMOOTH, and, fem. The sole (2nd sense), usually in the middle of the shoe, up to the heel. Instep made of leather. – One who is unfit (colloquial) infinitely inferior to someone. (pl. is. ) by someone who is very active, energetic | adject…. Ozhegov's dictionary

underwear – RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA, RCA. word forms

SUBSTITUTES – SOBIE, i, g. 1. foot, foot. Move the stitches in a hurry. My sole (my foot) overnight. The sole itches. 2. ironic. Address... Argo Russian Dictionary.

SUMMETTKA – LUBRETTKA, footstool, fem. 1. only in. action on the word sweep2 sweep1 (special). 2. a new sole, hemmed or padded to the worn, usually halfway. Doesn't fit or won't fit (colloquial) any person who... ...Ushakov dictionary

sock – sock, i, gen. pl. toch … Russian orthographic dictionary

sash – SMELT, i, pl. toque, d. tkam, g The lower part of a shoe, the second sole worn on the outside of the main shoe, usually in the midfoot, up to the heel. The sole of the right shoe is rubbed down to the inner sole... Dictionary of Russian terms

insole -i; Plural. toque, dat. toque; G. see also sweep 1) sweep II sweep. The hem of a finished dress. (2) A second sole, midfoot, attached externally to the main sole of a shoe; the whole sole to the heel. To change the sole …, dictionary of many expressions

SOMETHING - Insufficient. Red. clearly inferior compared to someone; inferior to someone in any way. RSFSR, 330; BTS, 213, 871; SPF 2001, 31; ZS 1996, 30; DP, 232, 427; Yanin 2003, 49; BMC 1998, 455. Not suitable as a replacement. Jarosz. Disrespectful … The Big Dictionary of Russian Proverbs

SUMMARY

See what 'sledgehammer' means in other dictionaries:

sledgehammer – … dictionary of usage of the letter jo…

RUNNING – ROMNEY, i, fem. The sole (2nd sense), usually in the middle of a shoe, up to the heel. Instep made of leather. – A person who is unfit, for whom (colloquially) is immeasurably inferior to someone. (jokingly) about someone who is very active, energetic. | Adjective…. Ozhegov's dictionary

instep – cinch, cinch, cinch, cinch, cinch, cinch, cinch, cinch, cinch, cinch, cinch (Source: Complete Accented Paradigm by AA Zaliznyak) … verbal forms

SUBSTITUTES – STITCH, i, g. 1. foot, foot. Move the stitches in a hurry. My sole (my foot) overnight. The sole itches. 2. Irony. Address… Argonian Russian Dictionary

footstool – footstool, i, gen. pl. toque … Orthographic dictionary of the Russian language

sash – SMELT, i, pl. toque, d. tkam,g The bottom part of the shoe, the second sole worn on the outside of the shoe, usually midway up the leg to the heel. The sole of the right shoe is worn down to the inner sole.

insole -i; Plural. tok, dat. I weave; G. see also sweep 1) sweep II sweep. 1) The sole of a finished cloth. 2) A second sole, metatarsal, applied externally to the main sole of a shoe; the whole sole to the heel. Change the sole ..., dictionary of many expressions

SOMETHING - Insufficient. Red. clearly inferior in comparison to someone; inferior to anyone in any way. RSFSR, 330; BTS, 213, 871; SPF 2001, 31; ZS 1996, 30; DP, 232, 427; Yanin 2003, 49; BMC 1998, 455. Not suitable as a replacement. Jarosz. Disrespectful … The Big Dictionary of Russian Proverbs

footstool - (1g); m. stitch, R. stitch … Orthographic dictionary of the Russian language

Craft material with patterns

In the development and production process, a shoe sole material is used that corresponds as closely as possible to the purpose and design of the shoe.

Modern industry uses the following types of raw materials:

- polyurethane. Represents a black-colored foam mass. It is characterized by low thermal conductivity, softness and light weight. Disadvantages include poor durability and rapid abrasion.

- Thermoplastic polyurethane. The material is obtained by injection molding. Such soles for shoes have density, wear resistance, presentable appearance. The disadvantage – low thermal insulation properties.

- Bonded polyurethane. The soles are made of two layers, resulting in density, wear resistance and protection against the cold. The disadvantage is that the two layers can separate from each other.

- Thermoplastic Elastomer. The material is porous, light and effectively protects feet from the cold. Despite their low density, TPE soles withstand friction well and have a long service life. The disadvantage is that the sole cannot be given a clear, even shape.

- polyvinyl chloride. This material is dense and heavy. It can be dyed any color during the production process. It is characterized by its reliability and durability. The disadvantage is the high specific weight.

- ethylene vinyl acetate. It is a vulcanized foam that has excellent elasticity, softness and resistance. Disadvantages - unstable at low temperatures, gradual reduction in volume under pressure.

- Synthetic rubber. This material meets all the requirements that are placed on high-quality shoes. Disadvantages - high cost of raw materials and high production costs.

- Tunit (kozhvolon). It is a composition of rubber, genuine leather. The cost of ventilating the base. The disadvantages of artificial leather are numerous - it is heavy, hard, quickly erased.

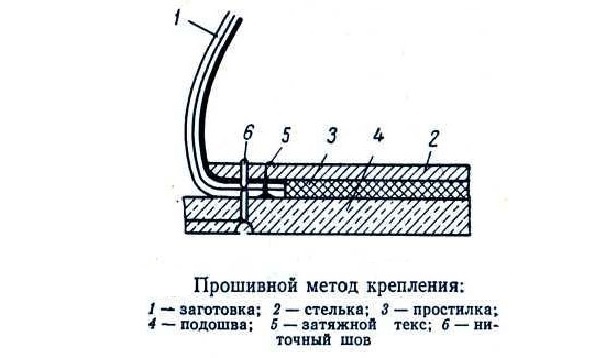

Method of attaching the sole

In today's industry, there are several ways to attach the upper part of the shoe to the sole. The choice depends on the intended use of the product, the type of model and the style of the shoe.

The connection of the parts is carried out by the following methods:

- sew up. Used in casual shoes and formal shoes. The upper is connected to the base with a strong synthetic thread. This option is considered presentable and sufficiently durable. This is also the case during the initial period of wearing. But over time, the suture material wears out and its durability decreases. Another disadvantage of this technique is that water enters through the holes. Today, the manufacturers do without this type of attachment.

- Pour. Creates a completely tight connection between shaft and instep. The leather or synthetic upper is lowered into a molded sole into which molten material is poured. After cooling, the sole becomes one piece with the workpiece. The advantage of this method is its durability and reliability. The downside is the poor adhesion of the sole to high-quality leather, which has low porosity.

- Glue. The most common method due to its cheapness, simplicity and reliability. The finished products are durable, wear-resistant and dense. The downside is the difficulty of choosing an adhesive for the sole, since different models use formulations that are resistant to different temperatures.

The quality of the connection between the sole and the upper depends not only on the method used, but also on compliance with the production technology.

Thermoplastic Rubber (TPR)

This type of sole material is rubber, which is derived from synthetic rubber. Any degree of flexibility can be achieved with it. The soles can be rough to the touch or completely smooth. The profile can be made in any depth and any geometric shape.

Thermoplastic rubber has a medium density and light weight, which makes this type of sole very attractive. Modern manufacturers have reduced the weight to a minimum. Thanks to good cushioning, these soles do not slip, and there are no negative effects on the joints and spine when walking. A pleasant surprise for the user is also abrasion resistance. Thermoplastic rubber is used in footwear such as sneakers and athletic shoes.

It is not suitable for winter - the surface is slippery and the material is not designed for cold temperatures.

construction of shoes

Shoes expert.

Contents:

- External components of the shoe upper

- Internal components of the outsole

- Intermediate parts of the workpiece

- External Components of the Shoe Upper Internal Components

- Internal components of the lower part of the shoe

A shoe, in the sense of an industrial product, is a construction made up of several parts that are assembled in a specific order. By using differently shaped parts and varying their number, it is possible to create models of all styles and functions.

Depending on their position in relation to the foot, all components of shoes are divided into two groups: uppers and lowers. The upper and lower parts become one with each other blank .

. The workpiece in turn consists of an outer part and an inner part.

The outer parts of a shoe upper

There are dozens of shoe models, each using a certain number of parts. However, some parts are found in almost all shoes, and some parts are only used in certain shoes.

For example, cuff

– is the cuff of a shoe that fits over the lower leg. The following accessories can also be found in

ankle boot

– The upper part of the shoe that fits around the ankle and part of the calf. As with the cuffs, the height of the shin can also vary depending on the shoe model. For example, the shin of a classic boot barely reaches the ankle, while a military boot has a shin that reaches mid-calf. The boot cuffs can be as long as possible and cover part of the thigh. Both the sole and the cuff are less prone to wear and tear and are therefore made of soft materials.

Another fundamental element of any closed shoe is the niche

. Only stretch models do not have them. The sash covers the upper part of the foot and forms an instep. It can be pointed or round. Due to its location in the most mobile part of the foot, the sulcus is subject to more wear and tear than other parts. It is therefore made from the most durable materials.

Disadvantages of textile shoes

- The shoe can get wet quickly and easily.. They cannot be worn in rain, dew or snow. Usually they are used in warm and dry seasons.

- are not permanent.. These shoes usually last 1-2 seasons. They are used in bad washing and drying conditions because as a shoe they can leak, fade or split open at the seams.

- They tend to stain easily.Especially when they get wet.

- Loses its attractive appearance faster.

- They are not cold resistant.

Those are probably the most important disadvantages. It can be said that these are more physical properties of the products in question, which depend on weather conditions and proper use.

Read more:- Mortar for soles.

- On the short leg.

- The sole is worn.

- What to do if the sole breaks?.

- Shoe sole to buy.

- rim on the shoe.

- Rubbing heel in shoes.

- Slipping heel in the shoe - what to do?.