Medi sells carbon-based insoles for shoes. The offer includes products for both adults and children. The models have a special support mechanism that shortens the adjustment time.

- The 8 best manufacturers of orthopedic insoles

- How to choose orthotics?

- Why do athletes need individual insoles?

- What do custom-made insoles bring to the athlete?

- Steps in making custom anatomical insoles:

- MODEL DESCRIPTION

- How does the insole manufacturing process work?

- Case study

- Prevention and treatment of gout in modern rheumatology

- What are custom orthotics?

- Performance engineering

- Who needs deposits?

- 3D orthotic insoles

- Who Needs Insoles?

- Video feedback from patients

- contraindications

- Benefits of custom insoles

The 8 best manufacturers of orthopedic insoles

*Overview of the best according to editorial expertsology.ru. About the selection criteria. This material is subjective, is not an advertisement and is not a buying guide. Before purchasing, a consultation with a specialist is required.

Feet health depends on the proper functioning of the feet, which are often exposed to vigorous physical activities. Orthoses are used here and can help with many problems.

To choose a suitable product, you need to know what to look for before purchasing. A manufacturer ranking based on important criteria and consumer reviews can help.

How to choose orthotics?

The most important criteria for selecting insoles are:

- Task. The model can have a preventive or therapeutic effect.

- Type of support. Orthotics can provide longitudinal or transverse support, and some provide both at the same time.

- material. Orthopedic insoles in shoes are usually made from leather and silicone. The first option is wear-resistant and retains its properties for a long time. The synthetic polymer adapts to the specific characteristics of the foot but wears out more quickly.

- Height. A multi-layer product with a supinating insole is higher than a massaging insole.

- Stiffness. The hardest ones correct deformities and combat foot pain, the semi-rigid ones help relieve pressure on the feet, the soft ones are used to prevent discomfort and are suitable for women's shoes.

- Size. Shoes should ideally match the length and width of your feet.

When it comes to price, every consumer will find a model that suits their wallet. Our rankings include both affordable providers and solid premium brands.

Why do athletes need individual insoles?

Smallest changes in foot position during movement:

– The knee joint deviates from its vertical axis;

– Any stress on the shoulder girdle aggravates the spinal deformity and leads to displacement of the internal organs.

What do custom-made insoles bring to the athlete?

✭ A feeling of comfort while exercising;

✭ Pain relief during sports;

✭ Reducing ankle and knee injuries;

✭ Reducing fatigue during sports;

✭ Reduction of foot, knee and spine pathologies.

Steps in making custom anatomical insoles:

- Analysis of the athlete's feet. This is carried out using a special podoscopic device. Analysis of foot geometry (podoscopy) makes it possible to assess the alignment of the feet with the detection of deviations, flat feet and relationships with the posterior, lateral and internal surfaces) of the entire lower extremity and the entire musculoskeletal system.

- Measuring and determining the size of a suitable insole design.

- Making an impression of the foot on the device (HDHDVAC 2). This is the most difficult and creative process. The contact between the technician and the athlete is very important here. The professionalism of the former and the attentiveness and patience of the latter.

- Warming up the insole. The finished insole is placed in a machine (MODUVAC), which, under high temperatures and vacuum conditions, prepares the insole for molding on a machine that has previously made an individual impression of the foot.

- The process of adjusting the insole. A process that is just as important as the production of the basic insole. This process of correcting and shaping the insole on a special machine allows the insole to be perfectly adapted to the figure skater's shoe.

Each person has their own foot shape, which differs anatomically (presence of calluses and flatfoot shapes). Therefore, making custom-made insoles is of great importance. The professionals of the 'Figurist' store are ready to offer them to you at a reasonable price. It should be noted that this process is quite time-consuming and requires an individual approach from professionals. Such a product is needed to improve blood circulation, prevent flat feet and reduce the load on the spine.

MODEL DESCRIPTION

Custom-made anatomical insoles are made in the 'Figurist' store, Leningradsky Prospect 44, by appointment by telephone: 8-495-542-68-68. Also in the store in St. Petersburg, 33 Griboedova Canal Embankment, tel. 8-812-645-77-88

Cost of making insoles: 3990 p.

In today's society, only 30 % of people do not have 'problems' with their feet (various forms of flat feet, corns, calluses and other anatomical anomalies), and the percentage of healthy feet in athletes is even lower. And if calluses and flat feet are an inconvenience for the average person, then for a professional figure skater they are a complication of the training process, a discomfort and, as a result, a lack of results and simply health.

How does the insole manufacturing process work?

The insoles are modeled in the athlete's shoes themselves.

The insoles are heated to a temperature that does not fog the foot, but is sufficient to develop the plasticity of the foam. The impression is taken in the neutral position of the foot when the axes are anatomically preserved. The insole achieves 100%ige pressure relief for the foot.

As soon as the insole has cooled down, the support is placed in the anatomically correct position. The pad that forms the transverse arch of the foot is adjusted based on the bony landmarks of the athlete's foot. And if this is not enough to align all body axes, additional elevations of the relevant areas of the feet can be formed using special correctors.

For maximum effect, separate insoles are made for the athlete's competition shoe. When changing shoes, it is always possible to adapt the old insole to the new shoe using special correctors. Insoles for everyday use can be transferred to each individual type of shoe - everything will work.

Case study

The insoles are made to prevent injuries. The team was pleasantly surprised: the heart rate at the same load was 5 % lower than before using the insoles. This suggests that the load is properly distributed between the leg muscles, which in turn increases the athlete's endurance.

The athlete complained of constant pain in her knee joints. She was unable to walk a mile without a nap or knee pads. You have to admit that it's pretty frustrating at such an age.

The specialists of the NL Clinic carried out a diagnosis under the podoscope and identified transverse and longitudinal flat feet. An examination of the muscles that support the arch of the foot revealed that they were weakened. And the cause was… a bad bite!

Kinesiology is concerned with untangling such tangled connections. To compensate for the faulty bite, the body sacrificed the feet of the deep muscle chain because it was more important to chew the food.

The muscle test spoke for itself. Correcting the bite took time, and the girl now wanted to train without pain in her knee joints. Doctors made insoles that support the arch of the foot, reflexively engage the muscles and relieve some of the pressure. The result: a marathon in 2 weeks without pain and kneecaps!

The athlete complained of lower back pain when squatting. Twelve pairs of insoles with different stiffness were tested in the clinic. The pain only disappeared with a couple. This pair was fitted to the foot and the insoles were fully effective. The athlete soon returned to his usual sports program.

Prevention and treatment of gout in modern rheumatology

gout – is a disease that mainly affects men with an active lifestyle and excessive consumption of beer, alcohol or large amounts of protein products. It is the most common cause of gout. gout is a metabolic disorder that results from a disturbed diet: excessive consumption of meat and fish as well as vegetable proteins or alcoholic drinks. Also contribute to the progressive development of gout goutare usually heavy physical strain and systematic overheating of the joints, e.g. B. through frequent sauna visits or baths.

gout can cause a number of side effects, including partial joint deformities in the toes, the appearance of so-called tophi or subcutaneous arthroplasties and the risk of kidney spasms. Ankle x-rays can also help make an accurate diagnosisgout 'Based on clinical symptoms and an ultrasound examination that excludes the risk of urolithiasis.

Further, gout causes a sharp increase in uric acid levels in the blood – a test may be required to determine this. Dangerous doses of uric acid in the blood cause acute joint pain as well as fever, swelling and mild skin laxity. To prevent the disease, it is important to follow a diet and limit the intake of alcohol and protein-containing foods.

The probability of suffering from a disease such as goutThe likelihood of developing gout is directly related to physical activity, which affects weight-bearing joints. For sports and gout prevention Gout prevention do you need Individual insolesFor sporting activities and gout prevention, you need individual insoles to distribute pressure and improve blood circulation. A sensible approach to exercise is not only a healthy lifestyle, but also a treatment that is suitable for gout. In any case, the treatment of such an ailment should be accompanied by visits to the doctor and regular use of medications that must be constantly combined. For this reason, at the first occurrence of such a disease as e.g goutIt is worth visiting a health center and getting advice.

What are custom orthotics?

Custom-made insoles are individually tailored to the user, taking into account all the characteristics of their foot. Factory-made orthoses, like custom-made orthoses, are designed to maintain the proper alignment of the foot, but when making them, the manufacturer is guided by the average consumer. For this reason, they are not as effective as a custom-made product, especially if correction is required.

- For the prevention and correction of flat feet, varus and valgus deformities of varying degrees;

- For joint deformities, especially if they are accompanied by pain;

- For proper cushioning when walking, especially if there are signs of developing flat feet;

- For athletes and people who have to spend most of their working time on their feet;

- In certain diseases such as diabetes, when the foot needs to be protected from friction and pressure, or in arthritis and arthrosis, when the joints need to be protected from excessive pressure.

Performance engineering

The Active-septer.com.ua website provides information about the production of insoles using various technologies:

- Thermoforming and profile grinding processes (America-Ukraine). With this technology, the inserts are made from American-made billets. High-temperature molding and grinding produces an insole that is fully customized to the shape of the customer's foot. The orthopedic insoles made with this technology have a comfortable recess in the heel area to protect the foot from slipping, an integrated supinator on the longitudinal instep and an increase at the level of the foot roll. The lower part, made of perforated polyurethane foam, non-allergenic and wear-resistant, is made of a rigid material that protects the foot from excessive shock loads. Along with the diagnosis, it takes from 2 to 7 days;

- German Ortho Systems technology based on blanks from the German manufacturer Imnotec GmbH. These blanks are modified during thermoforming. These insoles are suitable for pediatric practice - for children aged 12 and over. They have anti-allergic properties because the layer that comes into contact with the skin is made of vegetable tanned calf leather. The insole is 2 to 3 mm thick and can be adapted to all models, from boots to sneakers;

- Thermomodeling process (Ukraine-France). These insoles are custom-made for users ages 12 and up. Natural materials such as leather, Coloform and perforated Pedilin are used. The insole with a rigid base does not deform even if the user is overweight. Despite the rigidity, the insole is only 1-2 mm thick, so it fits any shoe model;

- Based on standard bark or pedilene inserts. The insole covers 2/3 of the insole length and has a recess in the heel area to protect the heel from slipping.

Who needs deposits?

insoles – is one of the conservative methods for correcting diseases of the musculoskeletal system such as flat feet, club feet, hollow feet, etc.

The human foot is as unique as your face. Standard insoles, made according to average parameters, are suitable for people with healthy feet who want to reduce the negative effects of movement loads on the musculoskeletal system.

Individually adapted insoles not only correct foot deformities, but also have a positive effect on other areas of the musculoskeletal system. By supporting the foot, they increase the efficiency of movement and relieve overload.

Wearing orthoses is recommended:

- Patients with foot pathologies: flat feet, club feet;

- Patients with arthrosis, osteochondrosis or spinal curvature, heel spurs, intervertebral fractures, varicose veins of the lower limbs,

- pain in the hips, knees, shins and feet;

- athletes, to reduce the load on the lower limbs;

- women during pregnancy;

- people who are overweight;

- People who spend long periods of time on their feet for work.

Regular visits to the podiatrist should be made throughout the treatment period to assess the effectiveness of the correction. If necessary, the deposits are changed or replaced with new ones.

3D orthotic insoles

Modern technology enables the production of custom-made insoles using the latest computer-controlled methods.

After a detailed examination, an individual fit is created:

- Scanning the foot with a special 3D scanner – converting the 3D image of the foot into a digital format.

- The pressure distribution on the foot while walking is measured on an electronic insole.

- The data obtained is processed by a computer program, the podiatrist makes individual adjustments if necessary, and the image of the future insole appears on the screen in 3D format.

- A special orthotic modeling machine creates your individual insoles according to the specified program with mathematical precision.

This technique makes it possible to create custom-made insoles that take into account all the anatomical and physiological characteristics of the foot.

This is important. Different insoles are made for each type of shoe (open shoes, closed shoes, sports shoes).

Who Needs Insoles?

- People with problems of the musculoskeletal system (not only children) – longitudinal and transverse flat feet, valgus position of knees and ankles, scoliosis, cervical or lumbar hyperlordosis, children with myotonic syndrome, with flat feet.

- Athletes – to correct and prevent misalignments of the lower limbs and to increase driving force during running and other sports.

- For people who are under excessive tiredness or pain in the joints and muscles of the lower limbs.

- People suffering from heel spurs, toe deformities, plantar fasciitis, Achilles tendonitis, stiff ankles and rheumatoid arthritis.

- Women during pregnancy or Frequent wearers of high heels.. After foot operations and joint endoprostheses (important - an adapted insole protects the 'new' knee or hip joint.

Made according to the individual anatomical features of the foot, insoles can correct flat feet and other pathologies. In addition, their use is associated with a number of benefits Advantages:

- Reducing pressure on the spine

- Relaxation of the muscles of the shoulder girdle while walking

- Stabilization of the ankles

- Leg length correction

- Reducing the load on the knee joints

- Reducing excessive supination and pronation

- Distribution of the load during prolonged standing work

- Improved blood circulation

- Alignment and balance of the central body axis

- Maintaining the aesthetic appearance of the feet.

- Help with flat feet.

The foot is an extremely important part of our musculoskeletal system as its position influences the position and function of other parts of the body such as the knee, hip and spine. Our experts prescribe custom orthoticsto restore the neutral position of the foot, allowing correct alignment of the entire body. The insoles are formed at the BRT center from a mold made of thermoactive material, that is, a material that becomes malleable at the right temperature. This means that an individual product can be produced for each customer. The production of individual orthoses is based on criteria such as age, weight and the presence of musculoskeletal diseases or other pathological changes in the body.

Video feedback from patients

Anna Melnikova

World champion in sports dance

I was in acute pain caused by a severe dislocation of my hand. An MRI scan revealed that there was a soft tissue tear. I was given 3-4 months to recover. I have been training for 2-3 weeks since the injury. My range of motion is already quite large.

Ekaterina Varnava

TV presenter, actress, participant in the show 'Comedian'.

I made a mistake and my ligaments were torn. I was told I had to put on a cast that would require me to walk for 1.5 months. That evening I went to Mykola Blum, who literally got me back on my feet in 3 days.

Irina Bodrova

Rehabilitation after a spinal injury

I practiced Aikido for a long time and sustained my back injury. I then consulted various chiropractors, physiologists and neurologists for 10 years. Everyone tried to help, but my life was filled with constant pain.

Varvara Zubova

European gymnastics champion

I came to the Biati Clinic for the first time five years ago. I had an ankle injury. Nikolai Yevelevich helped me recover. I started training immediately within 2 sessions.

contraindications

There is one contraindication: pressure-relieving insoles are not suitable for patients requiring orthopedic foot correction and consultation with a podiatrist.

During the consultation, the specialist asks the patient about his complaints. He then performs an examination that includes an assessment of the joints of the lower limbs, a measurement of the foot and a palpation with a GreeFoot podoscope. This device is a new generation device that provides a high quality and clear image of footprints on a flat surface in static mode.

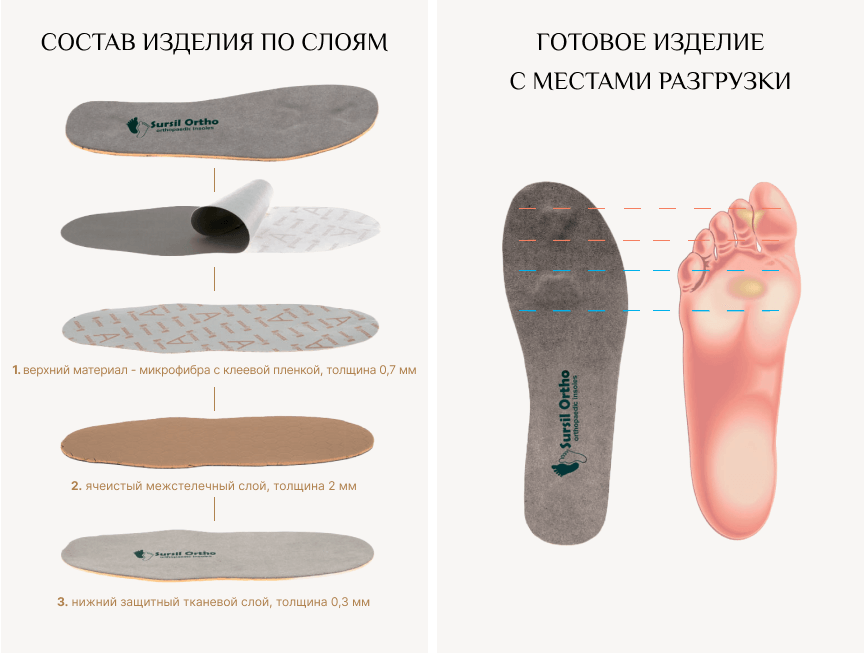

Making the pressure-relieving insoles takes around 30-60 minutes. The data is used to determine which areas need pressure relief and an insole blank is selected, removing the areas that need to be relieved. The patient is adjusted. If no adjustment is required, the insert is covered with an adhesive-based microfiber. The edges are cut to fit the inner contour of the shoe.

Benefits of custom insoles

Mass-produced products that everyone can buy for themselves are not suitable for everyone. In contrast, custom-made insoles fully correspond to the characteristics of the patient's foot, taking into account all the bends and areas subject to the greatest pressure. The specialists also take into account the patient's lifestyle and the type of footwear preferred. Such customized insoles have a number of advantages:

- They have a positive effect on the entire musculoskeletal system;

- they eliminate discomfort and pain;

- improve blood circulation;

- have a long lifespan;

- can be done quickly;

- can be corrected step by step.

The SM-Cosmetology Center for Cosmetology and Cosmetic Surgery offers high-level services. The equipment and medical devices have all the necessary certificates that comply with Russian state standards. To receive detailed information about making foot relaxing insoles and to make an appointment with a podiatrist, call the phone number or fill out the registration form on the website.

Read more:- Customized orthoses.

- Custom made orthopedic shoes.

- Buy insoles for flat feet.

- orthoses.

- Equipment for manufacturing orthopedic insoles.

- Manufacture of orthopedic insoles for children.

- Orteka – made-to-measure orthoses.

- orthoses for children.