In this case, the shoe must be sewn along the perimeter. A paragraph also needs to be added, but that's not the point of this post.

- How do you care for the sole?

- How to care for leather soles

- Cleaning the edges

- Edge and thread protection.

- Triple frame.

- Rapids on Veldtschoen construction

- Suturing process

- Sandal method

- §2 Insole

- § 3 Damping

- heel of the shoe

- Decorative frame. A small but nice detail.

- Combined fastening methods.

- Chemical fastening methods:

- What is an injured shoe?

- The second important criterion is the type and composition of the sole.

- Another element of shoe construction is the shaft.

How do you care for the sole?

When caring for a shoe, it is important to pay attention not only to the upper material, but also to the soles and welt (if any). Unfortunately, many men forget that these elements also need to be cared for, making them an embarrassing eyesore and causing the heel to break prematurely. In this article you will learn how to properly care for soles, heels and insteps and which products are best for these parts of the shoe.

It's simple: rubber soles are undemanding and require little care. You can brush them with a stiff-bristled brush, wipe with a damp cloth or rag, and rinse under running water to prevent water from getting on the top of the shoe.

The bottoms of rubber soles do not require cosmetic care, but the heel edges and ribs and the midsole (if present) require protection and sometimes even refinishing.

More about caring for seams and heel ribs later; Now we will deal with the care of leather soles.

How to care for leather soles

When cleaning leather soles, we recommend only using brushes with stiff bristles, which can be made of plastic or natural bristles. Many cheap branded products are suitable, but using expensive, high-quality brushes is pointless. Never wash leather soles with water, only clean them occasionally (if necessary) with a damp cloth.

Brushes to remove hard lint

If you plan to wear leather-soled shoes in rain and/or slush, you should use a so-called prophylactic or rubberized sole. Almost all shoe repair shops offer this service, but we recommend that you only go to a reputable and trustworthy company. The cost of installing a good prophylaxis usually ranges from 1,000 to 2,000 rubles.

Vibram prophylaxis

Prophylaxis is not necessary if you only plan to wear your shoes in dry weather and/or indoors. Additionally, leather soles are unlikely to suffer serious damage from a short walk on wet asphalt, but walking through puddles, slush, and snow can significantly shorten their lifespan. If you do not want to use prophylactics, you should use a special oil or other lubricant to protect the sole from moisture and reagents. We will discuss these products in more detail below, but we would like to point out that they cannot offer as good protection as a rubber prophylactic.

If you walk a lot, you should equip the leather soles with metal rails at the front. A proper service costs between 1,500 and 2,500 rubles in good workshops. These washers protect the leather soles from premature abrasion and wear. They are not always really necessary, as the degree of wear in the forefoot area depends on many factors: weight and gait, shoe design and sole quality as well as the type of surface. We would also like to add that it makes sense to polish leather soles from time to time.

Cleaning the edges

You need a small brush, which the English and Americans call a 'welt brush'. A good frame brush is made of wood with natural bristles (usually horsehair). You can buy these from Saphir, La Cordonnerie Anglaise or Siegol, for example. The brushes from these brands are of good quality and can last for a long time.

Of course, you can also use a new or old toothbrush to clean the piping if you want. However, there is a reason for the special brushes: They have different bristles, a larger bristle surface and clean the piping more effectively. I also find them more comfortable to use.

Cleaning a vacuum cleaner with a brush is easy. There is no trick, but as a precaution I would point out that you should rinse the brushes thoroughly from time to time.

Edge and thread protection.

The edge is made of leather. If you don't treat it, sooner or later it will be damaged. Even the threads, which are regularly exposed to moisture, dirt and sometimes reagents, can become severely worn over time if they are not at least occasionally soaked with a simple lubricant.

I use Saphir Graisse Dubbin (clear version) to maintain and protect the extractor and threads. Other similar waterproofing agents can be used - greasy, in low doses (Tarrago has relatively inexpensive versions; Tapir and Siegol are also worthwhile alternatives). Grease impregnations protect the piping and threads from moisture, dirt and chemicals and prevent premature wear of the piping and threads.

The grease can be applied to the puller and thread using special brushes. The same type of brush that is used to clean the squeegee is suitable. I personally recommend using a separate brush for cleaning the anvil and a separate brush for lubricating the anvil. If you prefer, you can apply the grease with your fingers or a cloth, but I prefer a brush.

High-quality grease is very economical and should be applied in small quantities. If the grease gets on the shoes, carefully remove it with a rag. Particular care should be taken if the waterproofing is applied to shoes with suede uppers.

I should add that I also treat the leather ribs with Saphir Graisse Dubbin. After the lubricant has absorbed and dried, I treat the sole ribs with shoe polish. I will probably write an article about waterproofing the sole ribs at some point.

How often should I lubricate the turnbuckles and threads? There is no universal answer here. Much depends on the intensity of use of a particular pair of boots and the environment in which the boots are used. Personally, I don't do this treatment more than once a month, and in the summer I usually avoid it altogether. If you only wear a pair of boots in good, dry weather and/or indoors, you should treat them once a year.

Triple frame.

This type is extremely rare. The only other shoe with this type of frame is British brand Grenson, and it looks very sturdy and quite unusual. It is an open, informal country boot that goes best with tweed and denim.

Grenson triple rib high boots

Of course, the triple frame provides maximum protection from moisture, but high-quality boots can be equipped with both a traditional and storm frame.

Rapids on Veldtschoen construction

The Veldtschoen boot is equipped with a standard welt, but the way it is sewn is unusual. A seam connects the frame to the lining and the back of the insole, one to the shaft and midsole and one to the shaft and outsole. The upper material is turned inside out and covers the frame.

Edward Green derby shoe with Veldtschoen design and classic frame

The outside of the Veldtschoen boot shows two seams that connect the frame to the shaft and the midsole and outsole. This construction offers maximum protection against water.

Suturing process

The sole is attached to the insole on a sewing machine with a single stitch through the sole, front edge and insole. The sole is threaded onto the insole of the shoe up to the heel. The heel part is attached with thread, nails or screws.

The sewing method has the big disadvantage that the sewing thread unravels very quickly and the sole falls off if even one seam is torn. Repairing shoes with cracked soles involves repeatedly piercing the sole and insole, which causes the edges to flake along the stitching line of the thread. Another disadvantage of this method is that when the thread seam passes through the insole, it lies on the surface of the insole, which is uncomfortable for the foot.

Previously, the suture method was recommended only for fastening soles in light shoes and sports shoes.

Sandal method

With the sandal method, the sole is attached to the tension edge with a circular stitch that is bent outwards by 90°, i.e. towards the edge of the sole. This method is characterized by the absence of an insole. To strengthen the seam and improve the appearance of the shoe, a decorative welt is added to the edge of the cutout when sewing the sole. The sandal method is not used on shoes with a textile lining, as the lining crumbles to the hem and the shoes look untidy. For this reason, the semi-sandwich method (double closure) is used for lined pieces.

The semi-sandwich method is characterized by the presence of an overlapping edge and the fact that the stretched edge of the workpiece extends to the front of the sole.

Sandals have a soft and flexible construction, good hygienic properties and low material wear.

§2 Insole

The insole forms the base of the foot and is the part through which the forefoot is connected to the sole (Figure 74). The insole adapts to the foot directly or using a glued-on textile lining. It must be flat and smooth, otherwise it will disturb the foot.

When the shoe is worn, the insole is subjected to repeated bending, which causes creases to form in the insole. Over time, cracks form in the folds and gradually deepen. Under the pressure of the foot, the insole expands, stretches and, if it is not strong enough or too thin, tears along the resulting cracks.

In addition, the insole is damaged by the sweat produced by the foot, which is deposited in the skin pores of the insole. Sweat causes leather to lose its elasticity and become stiff and brittle.

It should be borne in mind that in the manufacture of shoes, studs and threads are incorporated into the insole, which also has a destructive effect on the insole. From this it can be seen that the insole must be made of a durable and dense material.

The purfling must also be flexible and soft. As you know, when sewing rant shoes, the sole is attached to a rant, which is previously sewn onto the insole. If the insole is stiff and difficult to pierce with an awl, the rand cannot be sewn on. If the insole is loose and weak, the stitches may tear when suturing the wound.

The insole must have a certain thickness: 2.75 - 3 mm for men's shoes. 3mmFor men's shoes 2.75 - 3 mm, for women's shoes 2.5 mm. If the insole is too thin, the seams when sewing the edge will puncture the insole, which is undesirable.

§ 3 Damping

The heel back is the part of the base that is inserted between the top and the workpiece facing the heel (Figure 74). The rear part forms the heel pad, which must be designed in such a way that it does not restrict the movement of the heel, but also cannot migrate to the rear edge of the insole.

The heel pad also protects the heel from impacts and external forces.

For a shoe to be comfortable, the buttocks must be flexible and bend slightly under the pressure of the foot, but when the pressure is released, they should return to their original shape, which corresponds to that of the heel. Heels made of leather, granite, cardboard and other materials meet this requirement.

Handmade rubber boots use heels made of sole leather or leather. The leather used for the hems must be easy to work with, meaning it must be easy to peel (cut) and smooth. Leather that is difficult to remove (untreated, weak, too stiff or brittle) is not suitable for hemming.

A distinction is made between single-layer hems and double-layer hems. The latter consist of a hard and a soft layer. Heels for men's and boys' shoes: The single-layer heel should be 2.75 for men's and boys' shoes.for men's and boys' shoes 2.75 mm and for women's and girls' shoes 2.5 mm. mmand 2.3 mm for children's shoes for children's shoes 2.3 mm2mm; for shoes with two soles, the thickness of the rigid plate is 3 – 3.5 3-3.5mm; for two-layer buttocks, the thickness of the hard layer is:, the soft layer has a thickness of 2 to 2.5 2.5mm; soft – 2.5 mm..

The buttock must be firm, with the greatest firmness at the bottom where the buttock contacts the insole.

The heel height is measured at the center line excluding the edge of the frame and should correspond to the value shown in Table 6.

Heel height for different shoe numbers

heel of the shoe

The heel of the shoe is intended as a connection between the shaft and sole.

In most cases, this part does not carry any load, but is decorative, that is, it decorates the shoe by smoothing the transition from the sole to the working part.

Of course, shoe designers take this feature of the frame into account and pay special attention to this element in fashion shoes.

A frame is a narrow strip of leather or various types of rubber.

There are three main types of shoe lasts:

Decorative shoe edge.

As mentioned earlier, it is used to improve the look of the shoe.

It can look like a simple band that fits tightly to the sole, which when looking at the shoe can be seen as an extension of the shoe.

But it can also be contoured, made of PVC and even come in different colors.

This stitch adds strength to the seam and serves to connect the sole to the upper of the shoe.

It also greatly improves the appearance of the fastening of the sandal-like shoe.

This frame is particularly stressed because it connects the sole to the upper part of the shoe, usually through seams.

It is made of high-quality leather and of course must also be flexible.

Decorative frame. A small but nice detail.

continuation Ears of the gullible Picaboos to familiarize yourself with a typical shoe repair. Here.

Here you can clearly see that the frame is sewn. The question arises: What is sewn to what? The answer is: nothing. Just a thick thread on a thin base. You can even prick it with a needle. You can also put an advisor in the store who has a serious face and dawdles. This person believes that the shoes are sewn and therefore reliable.

Additionally, these shoes are difficult to break. Because the lining on the heel is completely frayed.

And the insole that was stuck there for some damn reason dried out. It's canon that you only stick in boots and underneath. Boots and ankle boots have an insole. When the insole shrinks, it still adheres to the rest of the glue and secures what has been achieved.

So the challenge first is to make sure the top doesn't fall off. Let's see what we have with the tread.

How well! The tread is already worn out. By the way, it's pointless to hammer the pebbles into the tread. You can damage the sole with scissors, a kitchen knife and a nail file. Even a tool can chip, especially if you do everything in balance. Plus, a pebble can bounce anywhere. You don't have to. Wear it as it is. Remove the stones and cut off the rest of the tread.

Combined fastening methods.

Fastening shoe soles is a combination of the methods from the first two groups (mechanical + chemical). These methods include nail glue, punch glue, rangle glue, double glue, stitch glue, punch glue, etc.

The sole is attached to the insole with nails through the heel cap and the frame edge of the shaft plate.

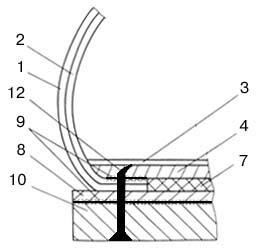

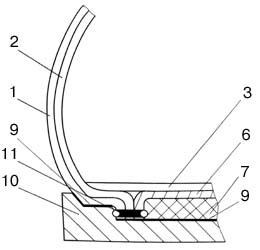

1 – upper, 2 – lining, 3 – insole, 4 – insole (main part), 7 – prosthesis, 8 – rear, 9 – glue stitch, 10 – sole, 12 – nail.

* Screw method. The outsole is attached to the insole using a metal wire through the tensioned edge of the upper material.

* Method of stitching. The outsole is attached to the insole with a thread up to the heel. The heel is attached with thread, nails or screws.

* Rant method. The outsole is attached to the shaft with a thread. The frame is threaded through the frame edge of the upper onto the lip of the insole and then the sole is sewn to it. The welt seams run parallel to the surface of the sole, the threads are located between the sole and the insole, so that the hygrothermal effect on the threads is low and the shoes have high performance and hygienic properties as well as good dimensional stability when exposed to direct impact. * Grinding process. The tension edge of the shaft is folded outwards, glued and sewn between the frame and sole. This method is characterized by the absence of an insole. Shoes made using the sandal method have a soft and flexible construction, good hygienic properties and a small material volume. *The Dopplet Method (Semi-Sandal Method). The sole is attached to the heel using the sandal method. The lining on these product parts is folded over the insole and secured with glue. The portion of the upper at the heel, including the lining, is attached to the insole with nails, screws or other rigid fasteners. The shoes are more dimensionally stable and stronger than sandals, have better hygienic properties and are more flexible.

Chemical fastening methods:

* Gluing process. The outsole is connected to the working element of the upper by an adhesive seam.

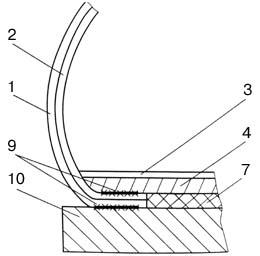

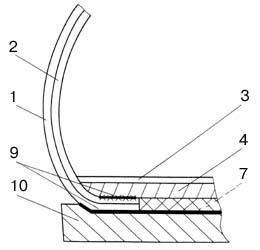

1 – shoe shaft, 2 – lining, 3 – insole, 4 – insole (base), 7 – spacers, 9 – adhesive connection, 10 – outsole.

* Casting process. The material for the shoe bottoms is injected into a mold where it is attached to the upper object with simultaneous shaping and finishing.

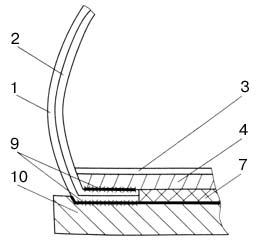

1 – shoe upper, 2 – lining, 3 – insole, 4 – insole (main), 6 – vtachnaya insole, 7 – prostilka, 9 – glue seam, 10 – sole, 11 – thread

* Pressed (hot) vulcanization process. In the mold, the raw rubber mixture is vulcanized under pressure and at high temperature at the same time, the outsole is formed from this mixture and attached to the workpiece in the shoe upper.

1 – shoe shaft, 2 – lining, 3 – insole, 4 – insole base body, 7 – spacers, 9 – adhesive seam, 10 – sole

What is an injured shoe?

STIVAN School of Shoe Crafts – protected entry

The Rant Closure Method and Its Variations. The peculiarity of making ranch shoes (Fig. 1) is as follows. The finish is formed on the last of the shoe and attached along the draw edge to the lip of the insole. The lip of the interfacing is then sewn to the calico using a single thread stitch across the back edge of the blank.

The strip is moistened and dried before sewing. The sole of the shoe is sewn to the edge; the seam that connects the sole to the edge is a single stitch that is placed in the sole blank. After sewing the sole, this seam is closed: the edge of the notch of the rubber sole is firmly glued, the notch of the leather sole is closed on a special machine with a wheel. This prevents the seam from fraying during the first period of wear. To fasten the soles and hems in Rant shoes, kapron or linen threads soaked in varnish are used, impregnated with polyamide to prevent slipping.

Rant shoes are mainly made with a frame in the heel area, the heel area of the sole is attached to the insole with nails.

The distinctive features of Rant shoes are the presence of a rant, the absence of punctures and fastenings on the insole (except for nails in the heel area).

Rant shoes are superior to other methods of attaching the insole in terms of their performance characteristics. The high durability is due to the fact that the thread seams are insulated from external influences and are not affected by sweat. The good hygienic properties of these shoes, especially the thermal protection properties, are due to the increased thickness of the insole, which fills the space along the lip of the sole. In addition, the relatively thick midsole helps distribute the load evenly across the sole, resulting in less abrasion.

The second important criterion is the type and composition of the sole.

The sole itself – The component that houses the tread, usually the stiffest part of the sandwich, which is responsible for the off-road characteristics of the shoe (grip on rocks, loose snow, ice, grass, etc.) and durability.

damping – Provides minimal shock absorption.

midsole – the nylon part that everything else, including the shoe itself, is attached to.

Steel insole – Some models use a steel insole to increase the rigidity of the sole and prevent punctures.

The materials used for each layer are diverse, ranging from old Ceprac formats to patented formulas made from rubber, rubber, ethylene vinyl chloride and other materials. Each has good qualities in its environment, but they are not universal.

In addition to the conventional soles, other variants are being added Variations of single and double breasted shoes. Rant – is a protrusion in the sole in the heel or toe area used to attach crampons, especially semi-rigid and rigid (automatic) crampons, used on mountaineering routes in the 'difficult' category. Soft soles, on the other hand, allow the attachment of virtually all types of shoes, even Uggs, and are also used on straight sections of ice.

Another element of shoe construction is the shaft.

Nose – The front of the shoe, its shape and the reinforced insole (if present) protect the toes from impact. Together with the boot's shaft construction, it protects your toes when descending.

back – The ankle area of the sock protects the heel and base of the ankle. Its main function is to prevent shock to the Achilles tendon and firmly protect the foot so that the toes do not dig into the ankle when descending.

Membrane shell – The inside of the boot has waterproof seams that ensure the boot is waterproof from the outside and wicks away moisture from the inside.

Boot lining – is the protective cover of the shoe that ensures resistance to abrasion and cuts. The most commonly used materials are natural leather (including suede and nubuck) and synthetic, quick-drying or waterproof materials with high resistance to mechanical damage.

Ribs and lining – Another important part of the shoe construction that is tailored to the individual and the thickness of the shin and calf muscles. If you make a mistake, you run the risk of scraping your shin, which will automatically result in you being unable to hike for more than a day. The tension is usually adjusted by the lacing.

insole – The quality and anatomy of the insole have a big impact on your well-being, from blood circulation to foot fatigue and headaches.

Bib height and number of lace hooks – is responsible for the safety of the ankle joint, and the number of lace hooks increases the variability of the laces for different purposes and the strength of the lacing.

shoelaces – I'm adding them as a separate item because they hurt me so much :)! In general, some shoelaces break quickly, and there are some that can unravel even with a quadruple slip knot under heavy dynamic stress.

Do you still think that choosing shoes is just a matter of pointing the finger at some more or less popular shoes at a reasonable price? If so, let's get into the details.

Read more:- The sole in the shoe is responsible for.

- Mortar for soles.

- Slipping heel in the shoe - what to do?.

- Damaged insoles in shoes - what to do?.

- Shoe sole to buy.

- What is an insole in a shoe?.

- Rubbing heel in shoes.

- insoles for shoes.