The average monthly salary in these companies is 98,600 rubles.

- A new plant for the production of medical devices for traumatology, orthopedics and prosthetics was opened in Moscow

- Implants of any complexity

- State-of-the-art technology in prostheses

- Get in touch with us in whatever way works best for you

- The stages of prosthetics

- The most important phases of the prosthesis fitting are:

- Basic terms and definitions

- Useful information.

- Ottobock foot prosthetics in Germany

- Ottobock knee replacement after amputation in Germany

- Indications for arterial prostheses of the lower limbs

- Preoperative preparation

- Lower limb prostheses

- The prosthesis can be obtained free of charge.

- variety of prostheses

- prosthesis program

- Pension for war veterans in 2022.

- About injured Russian military personnel

A new plant for the production of medical devices for traumatology, orthopedics and prosthetics was opened in Moscow

The individual care of the amputee is provided by an interdisciplinary team of occupational therapists, rehabilitation therapists, psychologists, orthopaedists, chiropractors and specialists for social and professional rehabilitation.

A production plant of the Federal State Unitary Enterprise (FSUE) CITO was opened in the Koptevo district. The ceremony was attended by Russian Industry and Trade Minister Denis Manturov, Russian Health Minister Mikhail Murashko, Russian Labor and Social Protection Minister Anton Kotyakov and Moscow Mayor Sergei Sobianin.

FGUP CITO, one of the largest medical device manufacturers in Russia, is responsible for the flagship project of the Russian Ministry of Industry and Trade to organize the production of medical devices for traumatology, orthopedics and prosthetics. The flagship project of the Russian Ministry of Industry and Trade to organize the production of import-substituting medical devices for traumatology, orthopedics and prosthetics within the framework of the state program 'Development of the pharmaceutical and medical industry'.

'This is a very important project. Important from the point of view of promoting cutting-edge technologies, replacing a huge flow of imported products and, most importantly, creating first-class medical products for thousands of Muscovites', according to Sergei Sobianin. – said Sergei Sobianin.

According to him, Moscow doctors perform more than 10,000 complex operations every year, and the new technology will allow the creation of orthopedic and prosthetic products for a specific person. High-quality and modern prostheses enable people to return to their normal lives.

«Of course, given the scale of the healthcare system in Moscow and the huge number of people who need this type of help, prosthetics and orthopedics, together with CITO we need to ensure a steady increase in orders from Moscow doctors. To do this, however, we have to convince them that we are dealing with high-quality products,' emphasized Sergei Sobyanin.

Implants of any complexity

On an area of more than 11,000 square meters there are almost 300 state-of-the-art technological devices: machining centers, machines for surface processing and application of functional coatings, 3D printers for the production of individual implants, as well as prosthetic and orthopedic products.

'In the Russian Federation, more than 600,000 citizens suffer from diseases of the musculoskeletal system. About 160,000. People need prostheses every year. And today we saw that on the site of this unique production complex not only modern high-tech products are manufactured that meet all modern requirements, but also conditions have been created for testing modern methods of rehabilitation,' said Anton Kotyakov, Minister of Labor and Social Protection of the Russian Federation.

A number of technological complexes at the enterprise were developed by Russian and foreign manufacturers specifically for the challenges of CITO.

The project has resulted in a complete production cycle - from the initial processing of semi-finished products to the sterilization and packaging of the finished medical devices. Technological possibilities allow the manufacture of implantable products of any complexity, with increased reliability and safety - the most important indicators in traumatology and orthopedics.

The company will also be able to manufacture bespoke prostheses and orthopedic products with increased functionality, allowing patients to regain the highest level of social activity. At the rehabilitation center, a multidisciplinary team of doctors and professionals (orthopaedists, neurologists, psychologists, rehabilitation therapists and prosthetists) will help you choose the right products and teach you how to use them.

State-of-the-art technology in prostheses

Thanks to rapid technological development and scientific advances, people with mobility impairments today have access to a wide range of prostheses and a variety of adaptive aids. The number of new developments and advances in this area is currently exploding, with the main goal being to integrate all the functions of a living hand/foot into an artificial limb.

So far, all available bionic devices (SmartHand, etc.) bear little resemblance to their natural counterparts, but researchers are working hard to eliminate this problem and continue to improve the prostheses. Particular attention is paid to the creation of high-quality feedback and an attempt is made to connect the patient's neural tissue and electronic devices into a (functional) whole.

It should be noted that until almost the end of the 20th century all prosthesis inventions were essentially mechanical, and in some models the flexion was adjusted manually. The main problem with today's outdated designs is their lack of flexibility and connection to the human body, as well as their short lifespan and unnatural, unsightly appearance. The prostheses that replaced the hand and foot in the past could not function as well as their counterparts and were not able to come close to their natural counterparts in terms of their capabilities.

Recently, a new trend in prosthetics has emerged, the so-called biomechatronics. The basic idea is to combine human nerve cells with robotics. Research in this field is currently focused on developing and improving artificial limbs that can be controlled by thought alone. Unfortunately, their functionality is still far from reaching the desired standard and does not allow maximum precision of movements.

Get in touch with us in whatever way works best for you

At this stage, all you have to do is let us know that all the necessary paperwork has been completed.

The components for the most effective prosthesis are chosen based on several factors, including the person's age, medical condition, and activity level. An average of one month elapses between taking the impression, making the plaster negative and positive, delivery of the components, fitting, cosmetic finishing and delivery of the prosthesis.

The stages of prosthetics

Creating an artificial limb is a complex and painstaking process. Each prosthesis is unique and the required components are selected based on a number of factors such as age, general health, activity level and many others. The production of an average prosthesis takes about two weeks.

The most important phases of the prosthesis fitting are:

- First consultation.

- Impression taking and anthropometric measurement

- Ordering the components

- Production of test sockets, adjustment

- Trying on the prosthesis with a trial socket

- Familiarization with the use of the prosthesis, if necessary adjustment of the socket shape and the prosthesis design.

- period of investigation

- Fabrication of the final shaft

- Delivery of the prosthesis

Our work is all about finding a solution that is unique and most effective for you.

Basic terms and definitions

It is very important to us that we speak the same language as you, so we have collected the most important technical terms and concepts in this section.

Yielding – Bending under load against damping resistance until a specified bending angle is reached.

Yielding - Deformation under load against damping resistance until a specified bending angle is reached.

Useful information.

According to the Federal Law of 11/24/1995 № 181-FZ 'On Social Protection of the Disabled in the Russian Federation', every disabled person has the right to prostheses and to free technical rehabilitation measures and services at the expense of the federal budget.

Because we care about your convenience and want to save you time and effort, we will help you free of charge with the formalities to obtain compensation for the cost of the item:

– Application for compensation to the Territorial Branch of the Social Insurance Fund (STF);

– a copy of your certificate of incapacity for work,

copy of the IPRA;

– a set of documents that you received after fitting the prosthesis.

The competent authority must issue a compensation notice within 30 days of receipt of your application. The agency is obliged to transfer the amount to you within one month of the notification of payment.

Ottobock foot prosthetics in Germany

Ottobock foot prostheses with ankle modules offer patients the opportunity to return to their normal life and even to sport after a lower limb amputation. Maximum restoration of the function of the natural ankle frees you from having to control every step. The aisle looks free and natural. One of the best examples of prosthetic feet from Otto Bock:

- Foot 1C40 C-Walk. An additional C-spring made of light and strong carbon fiber, which is structurally connected to the foot's main spring mechanism, relieves both limbs and allows the artificial foot to roll naturally and have an easy, springy gait;

- Foot 1D35 Dynamic. Designed for patients accustomed to moderate physical activity and who have had a leg amputation at below or thigh level and disarticulation (hip or knee disarticulation). Offers a natural gait and the possibility of wearing open toe shoes thanks to the excellent details on the outside;

- Foot 1C30 Triassic. The unique design of the two spring elements, which are connected at their curved sides, absorbs shock when walking and ensures a characteristic natural heel-to-toe movement of the foot. Allows easy walking on different surfaces and at different speeds. Suitable for users weighing up to 125 kg who prefer moderate to vigorous physical activity;

- Foot triton. The construction of three bonded, strong carbon and polymer springs allows the biomechanics of the natural foot to be reproduced at all gait speeds and strides. This prosthetic foot is even suitable for running and other sports activities;

- Foot Triton smart ankle. Bionic prosthesis with microprocessor controlled hydraulic ankle module system. Their combination with the underlying carbon spring gives the foot unrivaled freedom of movement at different speeds on different terrain and any surface condition;

- Foot meridian. A bionic prosthesis that creates the conditions for maximum dynamics and stability. In addition to the axis of movement in the ankle, it has additional axes in the sole, which significantly increases mobility. It 'recognizes' steps, inclines, declines and other changes in terrain and surface conditions immediately.

Ottobock knee replacement after amputation in Germany

Patients who have had their thigh or more amputated need to have a knee replacement. Modern Ottobock models enable their wearers to actively participate in life - at work, walking, cycling, playing with children and pets and doing sports. The popular knee joints from Otto Bock include:

- The 3R60 EBS knee joint. The hydraulic system integrated into the knee prosthesis enables gentle and natural movements that resemble the gait pattern of a healthy person. The prefix 'EBS' stands for 'ergonomic gait balance' and reflects the prosthesis' innate ability to move confidently at any speed, including on stairs and other uneven surfaces;

- 3R80 knee joint. A prosthesis that meets high demands for maneuverability for patients weighing up to 150 kg. The hydraulic system controls all phases of knee movement, both when supporting the prosthesis and when transferring body weight to the healthy leg. This allows for fast, natural, and safe movement, including walking up inclines, stairs, and descents. The prosthesis is waterproof and can be locked manually on slippery, wet surfaces if necessary, ensuring the highest level of safety;

- C-Leg 4 prosthesis system. With this system, the Otto Bock Group heralded the era of microprocessor-controlled hydraulic prosthesis systems. The bionic C-Leg 4 prosthesis not only adapts to the patient's natural shape, but also to the gait pattern;

- Genium prosthesis system. Otto Bock is now presenting new, more modern modifications of the Genium bionic system. These are still microprocessor controlled to achieve a natural gait, but have been enhanced with options for double amputees and can be controlled via mobile apps. Free walking up and down, walking backwards and automatic balance control are just some of the features of the Genium system;

- Genium X3 prosthesis system. It is the next step in the development of bionic prostheses on the Genium platform. Compared to previous models, this system is more corrosion-resistant, moisture-resistant, resilient, allows for swimming and a quick transition from walking to running and back again. In other words, its users can lead very active lifestyles.

Indications for arterial prostheses of the lower limbs

Surgery is indicated when the long arteries are severely damaged - more than 50 % of the diameter of the arterial trunk is blocked. Symptoms include pain in the legs at rest and when walking short distances (less than 200 meters), and the formation of trophic ulcers on the legs and toes. Peripheral leg artery aneurysms and other pathologic conditions where blood flow to the affected area is severely restricted and medications are ineffective may also be candidates for surgery.

This technique is used in cases where endovascular dilatation is considered ineffective.

A contraindication to the procedure is the development of wet gangrene of the limb, complicated by a septic condition.

If the length of the narrowed section of the artery does not exceed 7-9 cm, the doctors of the Surgical Center perform another operation - endarterectomy, during which essentially the layer of the inner vessel walls that blocks the lumen is removed.

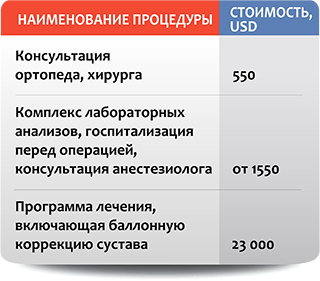

Preoperative preparation

Arterial prosthetic surgery in the surgical center is preceded by a comprehensive diagnostic examination of the patient.

- Echocardiography (ECHO) - This ultrasound scan is used to determine how the heart is working, its structure and any clots in the heart's chambers.

- ECG and consultation with a cardiologist.

- X-ray of the organs in the chest cavity (lungs, heart).

- Laboratory diagnosis of urine (general analysis) and blood (general and biochemical parameters, urea, coagulation, total protein, rhesus and group, electrolytes, infection groups).

- Esophagogastroduodenoscopy (EGDS).

Lower limb prostheses

Modern technologies in lower limb prosthetics include the best specialists, the latest devices and the modular principle of prosthesis construction. All these features contribute to an improved quality of life for our patients. Components from the world market leaders in prosthetic technology. The highly qualified specialists of the Barrier-Free Group will help to choose a prosthesis model adapted to the patient's activity. The prosthesis socket is the link between the prosthesis and the residual limb. The prosthetist works closely with the patient to ensure all anatomy is considered and the socket is accurate and correct. In this way, the patient can move with the prosthesis at different speeds in any weather and also on uneven terrain without pain or strain.

The prosthesis can be obtained free of charge.

youtube

youtube  Instagram

Instagram

Address: g. Moscow Nikitinskaya ul. 13A

Creation of the website – VeryGood

Address: 13A Nikitinskaya Street, Moscow

Phone: +7 (499) 288-14-75 Website Creation - VeryGood

variety of prostheses

functional skills and Price of lower limb prostheses can be very different. Especially in the Israeli lower limb prosthesis centers, the price of the treatment program depends primarily on the type of lower limb prosthesis.

The following prostheses are available for patients in Israeli hospitals. The following types of prostheses are available:

- Proprio foot – A functional prosthesis that replaces part of the leg from the knee and can be adjusted to the patient's individual gait, facilitating stair climbing and many other activities.

- Element DS – A comfortable design that uses composite materials to support the leg in various load vectors, allowing smooth and easy movement for the patient.

- C-Leg – is an innovative prosthesis with a microprocessor inside. Offers revolutionary mobility options for transfemoral amputees. Read more…

- Diagnostic examinations (computed tomography, laboratory tests, X-rays, electromyography).

- Advice from an orthopedist.

- Preparation for fitting the prosthesis.

- Adjusting and adjusting the prosthesis.

- Dynamic Monitoring.

An important factor for patients is the affordability of prostheses in Israeli medical centers. However, when reviewing lower limb prostheses in Israel, the adaptation of the prosthesis to the patient's individual aesthetic ideas is also highly valued. Cosmetic fittings on a prosthesisCosmetic coverings on the prosthesis also prevent wear and tear caused by friction.

prosthesis program

As the acetabulum of the residual limb is very important for the reinforcement and functionality of the entire prosthesis, the latest high-quality materials are used. It is often made from thermoplastic sheets and laminates. The socket is precisely adapted in plaster to the anatomical conditions of the residual limb, on the basis of which the residual limb is made.

According to most physicians, idiopathic pain in the amputated limb occurs because impulses continue to be transmitted to the severed nerves in the residual limb, creating the feeling that the limb is there. Factors that provoke phantom limb pain include environmental influences, especially exposure to various electromagnetic impulses.

The current method of overcoming phantom limb pain is to wear special knitted or silicone sleeves with metal threads woven into them that create a protective barrier to shield the residual limb from external electromagnetic influences.

Patients of different age groups need a prosthetic leg. Of course, the level of physical activity in different age groups varies greatly. Currently, all major manufacturers of prosthetic materials rely on activity level to classify their products.

For example, the following picture emerges for the four prosthesis groups. The first group corresponds to the lowest level of activity and includes prostheses designed for indoor mobility, the second group includes prostheses designed only for short-term outdoor mobility, the third group includes prostheses with a range of mobility limitations, and the fourth Group includes prostheses that allow full mobility.

Pension for war veterans in 2022.

Benefits for war veterans are established based on three benefit categories: insurance benefits, ie, disability and military pay, Social Security benefits (in the event of disability), and a government payment (pension) – only veterans receive these. The latter consists of the following parameters: length of stay in the armed conflict; awards, injuries; status during participation in armed conflicts (rank, type of post); Duration of Service.

There are also tax breaks for veterans: for vehicles, real estate and other property such as garages and parking spaces. The prerequisite for the tax exemption is that the property is not used for commercial purposes. The exemption can only be granted for one property.

The Kremlin website announced on March 5 that in the event of the death of a Rosgvardia officer participating in a special operation in Ukraine, his family will receive 5 million rubles. The same applies to soldiers who took part in a special operation in Syria and to those who died within a year of being discharged from duty due to an injury or other trauma sustained while on duty.

In addition, military personnel in Syria or the Russian Guard in Donbass who received injuries, bruises or mutilations will each receive 3 million rubles. In both cases, the payments are made as a lump sum.

About injured Russian military personnel

On March 27, Channel One TV broadcast footage of soldiers injured in a special operation in Ukraine being presented with Orders of Bravery and medals at Vishnevsky Hospital in the Moscow region.

Social media users pointed out that the veterans received the medals in wheelchairs and hospital beds, many of them without legs and some without an arm.

Orders of bravery and medals for bravery were also awarded in the Burdenko Hospital. Russian Deputy Defense Minister Yunus-Bek Evkurov wished the legless soldier 'to recover and get back on his feet'.

- prosthetic legs.

- prosthetic leg.

- Modern leg prostheses.

- Leg prosthesis below the knee.

- Limb prostheses are.

- prosthetic leg where.

- prosthetic foot.

- finger prosthesis.