Stiff footwear affects joints, calluses, warts and even deforms the foot. Varicose veins, the development of longitudinal flat feet, plantar fasciitis and salt deposits in the heel bone can be unpleasant consequences of wearing uncomfortable shoes for a long time.

- Satan's claws and 'elk hooves': the most unusual shoes in the world

- Claws of Satan

- What do the shoe models look like?

- How many mold holders should I buy and how should I use them?

- Advances in Shoemaking: How Technology has Changed in the Last Hundred Years

- What does good hoof quality mean for shoes?

- Hoof variants for shoes

- 19 Replies to 'Different Types of Shoe Insoles (Shapers)'

- How to make upholstery at home

- Shoe last pattern

- HOW SHOE LASTS WORK

- Technical requirements for shoe lasts

- conclusion

- How do you choose 'your' pair considering fit?

- Cedar Woodlore combination shoe spacers

- Shoe spacer made of beech wood Dasco

Satan's claws and 'elk hooves': the most unusual shoes in the world

Imagine you are a medieval knight, circa the 12th and 13th centuries, and you leave Europe for a few years to complete an important mission: the Crusade. What would you take with you as a lasting souvenir? For example, babushi, comfortable Persian shoes without heels. Not bad for walking on the cold stone slabs of a castle.

But medieval fashion was sometimes more ruthless than the Inquisition. A few decades later, the comfortable babuschi became sweaters. The toe of the shoe reached up to half a meter, and the size of the shoe now had a special meaning - the longer, the richer and more noble.

Why were heels considered a symbol of courage? How did military boots come into fashion? And why did Americans put wooden soles on their shoes? This is the topic of, among other things. 'The Unknown Story' with Boris Ryzhov.

Claws of Satan

Shoes called 'Satan's claws' were very popular in Europe in the 14th century. They were made from leather, velvet or silk. The pointed nose, reminiscent of a bird's beak, could be up to 70 centimeters long.

'Many fashion-conscious men even had to tie this long part of the sock to the knee joint with a rope or chain,' he saidnotes fashion historian Lidia Sokolova-Serbska, doctor of history.

But only princes and counts could afford such luxury. Knights had to wear more modest shoes with a nose length of no more than half a meter. Commoners had to make do with little - the 'bow' of their shoes should not be more than 15 centimeters. Pullens didn't go out of fashion for a hundred years. It was not until the 1560s that they were completely abandoned.

'Pulls were of course impractical, like any item used to display one's wealth'. – says fashion historian AKK, who is credited with creating the iconic pullen.says fashion historian Asya Alajalova.

What do the shoe models look like?

The most affordable models are made of plastic. This is the 'cheap and sour' version. Yes, they help shoes keep their shape and can smooth out kinks and wrinkles, but they don't absorb moisture, neutralize odors, and look very cheap. In addition, plastic shoe mold holders usually only fill the front part of the shoe.

Sapphire plastic shoe shape holder.

If possible, always buy mold holders made of wood and not plastic. They come in many varieties, and not all of them are worth considering. Painted models in particular are not recommended, because although they look chic and expensive, they absorb little moisture and have odor problems. Unpainted models are accordingly better. The type of wood is not particularly important, but many buyers like cedar wood for its distinctive smell and antibacterial properties. Beech, birch or other woods can also be purchased, especially if they better suit the size and shape of your own pair.

Loake wooden shoe lasts

We should add that wooden strips can be classified not only by the type of processing and type of wood, but also by shape/type. The cheapest models only fill the front part of the shoe, while the back part can be filled with a wooden-tipped spring - there is then a risk of deformation of the shoe/foot. More expensive models only partially fill the back of the shoe, while the best models fill it completely. These are to be preferred.

Berwick shoe insoles with heel pads

Many classic shoe brands offer shoe insoles under their brand name that can fit perfectly on shoes and boots from the same manufacturer. However, they do not always fit perfectly on all models, as some brands have many pads and multiple attachments. In addition, in some cases, mold holders from brands that specialize not in shoes but in their accessories - Avel, Saphir, Tarrago - can be a good choice.

How many mold holders should I buy and how should I use them?

Ideally, you should purchase mold holders for every pair of classic shoes. You can also just buy one set initially and use it for all your shoes as needed. When you get home in the evening, insert the shape retainers into the pair you wore. Don't wear the same shoes the next day - they need to 'rest' and dry. In the evening, when you get back home, you can take out the mold holders from the pair you wore yesterday and put them into the pair you just took out.

Regularly remove the mold from your shoes and boots and let them go out into the fresh air - not near a radiator or heater!

Advances in Shoemaking: How Technology has Changed in the Last Hundred Years

A hundred years ago, the technology of making shoes was completely different than it is today. Back then, a cobbler had to draw the last of a shoe on paper and create a model that was comfortable and a perfect fit for the wearer. Thorough knowledge and a wealth of experience were the guidelines for the craftsmen of that time. Of course, there weren't as many models back then as there are today, but that doesn't detract from the complexity of shoe manufacturing.

Today, drawings and hand carving have been replaced by computer-aided design. Special programs make it possible to create all models and shapes without much effort. The design is now based on average values, which make it possible to design the optimal shoe for the vast majority of customers. The materials have also changed: from wood to plastic or metal.

An anecdote from a shoemaker. The Italian shoemakers say: 'No matter what we do, we make Italian shoes! Our cobblers say: 'But we make them like the Italians'. It is worth noting that domestic shoes have recently increased in quality.

What does good hoof quality mean for shoes?

There is no doubt that the hooves play a key role in the comfort of the shoe. For example, if the height of the shoe is too high when the raw material is cut and the insole is too narrow, a tight fit is guaranteed. So the fit of the shoe determines how comfortable the shoe will be. Experienced shoemakers claim that 8 out of 10 women should judge a pair by the heel.

Heel pads are designed for specific shoe models, boots or sneakers. The heel height is also not without padding. As you can see, there is no doubt about the number of lasts and their role in producing high quality and comfortable footwear.

Hoof variants for shoes

If you decide to buy good, expensive shoes, it is worth considering purchasing special insoles, sometimes called spacers or shaping insoles. The English use the simple but somewhat obscure term shoe trees, which literally means 'shoe trees'.

Surprisingly, there are many types of shoe trees - and so I decided to write a long article giving an overview of them. I would like to emphasize once again that these are accessories and not the lasts onto which the shoes are sewn.

This is the cheapest option. You are most likely to find these spacers in multi-brand discount shoe stores, as well as small shops and kiosks that sell shoe cosmetics. Sometimes they cost less than 100 rubles (at IKEA – only 59 rubles!); the most expensive - the Saphir brand - are made in France and cost about 600-650 rubles.

But even the French plastic partitions are a bad choice, a classic example of the 'cheap and serdito' series. Unlike wood, plastic cannot absorb odors, absorb moisture and do not help dry shoes.

And the partitions as such have another disadvantage. They are not inserted completely into the shoe like full-fledged insoles, but are curved. The end, which is connected to the front of the spacers by a thick metal spring, must be bent and inserted directly into the 'heel' of the shoe. This naturally puts pressure on the heel area and the back of the shoe and the back of the insole can deform over time.

This is a better option than plastic spacers, but worse than wooden shims. Wood absorbs moisture and eliminates odors, which is a good thing. However, the flaw in the spacers described above remains. Of course, you can simply push the spacers into the shoe without retracting the toe, but then the wrinkles will not be smoothed out, but the shoe will generally feel good - thanks to the properties of the wood already described.

19 Replies to 'Different Types of Shoe Insoles (Shapers)'

I use cheap plastic shoe insoles wrapped in paper. The paper absorbs moisture and odors and is very hygienic it seems.

Have you ever worn satin shoes? I like sneakers http://www.adidas.ru/krossovki-zx-flux/B34485.html But the satin upper is alien to me. Do they last long?

1 Thank you for your website. She is very informative.

2 – I have always bought Woodlore shoes. They are optimal in terms of the price/performance ratio. But now it is difficult to buy them in Moscow, they are American. Avel are decent budget pads, but they have an odd size range. My husband is a size 42.5 and the 42-43 insoles are hopelessly small. The 44-45 insoles fit a size 44 shoe, but I like my shoes to sit tighter on the insoles. With the size selection of 40-41, 42-43, 44-45 I will not be able to fit my husband. He's not too keen on buying insoles more expensive than 3k for 10-15k shoes (that's what we buy, or cheaper if there are discounts). We would love to buy the insoles with the shoes, but the offline stores don't have them in the mid-price segment.

I would also like to add that in addition to wooden and plastic molds, there is also a very good and not so expensive alternative - foam molds with an antibacterial substance. They are available with both handles and springs and in various shapes - especially for boats, bed covers, ballet apartments... Take a look at the NICO Germany brand.

Dimitri, tell me. What about winter boots with fur? The idea is that insoles that are permanently stuck in the shoes put pressure on the fur.

In Western Europe people rarely wear boots with fur…. Personally, I only put inserts in my winter boots every now and then, and I haven't found them ruining the fur - but when you have boots on, your feet also put pressure on the fur - so even without inserts it's still the same Changes over time and generally degrades little. Apart from that, the interaction with the cedar wood is also good for the fur - it minimizes odors and wicks away excess moisture.

When I put my winter boots away for the winter, I fill them with crumpled paper or newspapers without any noticeable smell. By the way, this is the cheapest alternative to insoles, although not entirely complete.

How to make upholstery at home

Once you have prepared everything and taken the necessary measurements, you can get to work. The execution plan is quite simple, follow the instructions below.

- Put a bag or sock over your foot and start securing it. Stick with tape in one color.

- Cover the entire foot with a different color of tape. This will ensure there are no gaps. Repeat this process several times..

- Now Cut a piece Tape off along the front line. Be careful not to damage the leg. Repeat this process twice, on the left and right sides.

- Fill the resulting cavities with newspaper or mounting foam to give it rigidity.

- After filling Seal the cut out area with tape. If required . Add more tape and foam to the inside of the workpiece.. So you get the desired size of pads for every type of work.

If the final size does not fit your foot, you can adjust it. Carefully trim the edges or add material if necessary.

If you did everything right, you should have a great pair of washers. You can use them for all kinds of manipulations on your shoes. If you want, you can also use it to make your own slippers.

Shoe last pattern

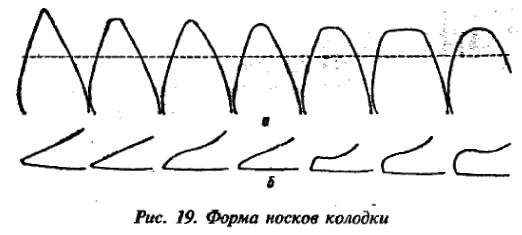

The shape and size of the forefoot (last) as well as the shape and height of the heel determine the style of a shoe.

Changes in shoe lasts are associated with changes in shoe fashion and are determined by the general direction of clothing modeling.

Depending on the hoof, the toe can be wide or narrow, blunt or pointed, oval or convex, elongated or blunt, high or low.

Drawn wedge hooves are used for outdoor shoes. With these insoles, the upper, removable part (wedge) is held in position by a spring-loaded closure in the rear part of the insole. The advantage of this type of shoe is its rigidity, which comes into play when forming the footprint and gluing the sole. Removing the wedge before removing the shoe from the last largely prevents the half-finished shoe from tearing and significant deformation of the shoe*.

Hinged lasts are used for outdoor and sometimes indoor shoes. Articulated lasts have the advantage that the shoe is removable.

Articulated lasts have the advantage over other lasts that the shoe can be removed from the last without deformation.

Attachable strips (Figure 20)

The liner molding method uses washers. Depending on the version, retractable strips can be extended by 9-16 mm.

Double shoe lasts are used in the manufacture of sandals and reversible shoes, as well as in the manufacture of slippers.

HOW SHOE LASTS WORK

Technical requirements for shoe lasts

Tension blocks have a tolerance for deviations from the gauge of up to 1 mm in length and up to 0.5 mm in width. For the volumetric dimensions, deviations of 0.55L, 0.72L and ti.68L to 2L from the circumference are permitted.

When testing blocks with templates in the top and cross section, the following deviations are allowed: 0.5 mm less in the cross section on each side and 0.5 mm less in the cross section in the longitudinal direction, at individual points and at the bottom along the track.

The right sole must correspond to the left sole in shape, size and fullness.

The cleats must be free of cracks, rot, wormholes, knots in the wedge line and the cleat attachment at the toe and heel, and also at the chin along the trailing edge using the edge and glue method. The cleats must have clearly visible markings of style, size and completeness . The metal plates should be firmly connected to the shoe tracks and the wedge should be firmly connected to the shoe body^.

Wooden stoppers should be inserted flush with the metal. The wood of the finished wedges must not contain more than 8±2 % moisture, otherwise the wedges will dry out, change dimensions and crack during use.

Methods for controlling wedges. The dimensions and shape of the wedges are checked using test points. The test points are placed in the form of notches on wooden panels and in the form of 'beacons' on uncut polyethylene panels.

The notches or 'beacons' used to check the dimensions of the chocks are placed in the following locations

on the heel on the side panel, two punctures on each side near the back of the heel mark in sections 0.G7L and 0.18L;

on the heel: on the back of the shoe, at a distance of 0.551h, rising perpendicular to the axis of the back and crossing the profile of the longitudinal axis of the back;

in the gutter, the upper point on the web at a distance of 0.72L', the measurement deposited along the axis of the web and raised perpendicular to the intersection with the profile of the web, the lower points on the edge of the web in one Distance of D.68L, the measurement being deposited along the friction of the pad along the axis. The puncture points on the heel are used to check the shape of the heel part of the shoe, on the heel and frame to check the circumferential dimensions (with an elastic band).

The height of the heel from the support surface is measured vertically using a metal square at the heel curve along the axis.

The performance of the cleats is determined by a multiple* of the refraction. The fitting must withstand at least 600 refraction cycles.

Influence of the hooves on the quality of the shoe. The condition of the hoof significantly affects the quality of the shoes produced. The following causes can lead to a reduction in the quality of footwear

– Deviations in hoof dimensions

Deviations in hoof dimensions that go beyond the values permitted by the standards;

– Unevenness of the right hooves in shoes of the same type and size,

Variation in size and fullness between right and left hoof;

– Shrinkage of strips with high humidity in rooms with low humidity.

Drying out in rooms with high humidity and absorbing moisture through thinner hooves, causing swelling and dimensional errors

– Poor machining (deburring) of metal parts

The shoe is not properly sealed in the heel area or throughout the last, which may result in damage to the lining and upper during the molding process;

– A loose, unbound shoe wedge

Wooden or plastic plugs that are not flush with the metal plate; and misalignment of the components of the combined hoof;

– Production of bales that are unrepaired and untreated

Bales that have not been processed or repaired

– Faulty seals (cracks, chipped wedges, rotted wedges, blackened wedges, etc.).

Use of improperly constructed wedges (cracks, rot, knots in the wedge line, knots in the toe area, knots in the heel area, knots in the blocking edge of the round hoof of the shoe).

Methods of shoe care, storage and repair. Shoe tips require special care.

The studs should be stored in dry, heated rooms at a temperature of 16-20 *C and a relative humidity of 40-60%. Polyethylene posts must be protected from direct sunlight. The strips should be stored in a shelving system with boxes for models, sizes and fillings. Make sure stocks are stored in pairs. Inventory is checked at least quarterly. Unsuitable blocks are removed from production and blocks in need of repair are repaired. Unusable coverings are coverings with a damaged rotation mechanism, coverings with a broken upper disc, cracked or deformed toe and heel parts, cracked side surfaces, lost wedges and coverings whose dimensions do not meet the standards.

Upholstery with nail or stud impacts, partially chipped top pads, and partially damaged locks and pivot mechanisms should be repaired if possible.

Repair the damaged backrest and top platform by gluing and nailing pieces of leather. Chisel out the broken pieces with a chisel. Glue an appropriately sized strip of hard leather into the resulting groove and secure it. Chisel out the broken portion of the padding and replace it with a piece of leather of the desired thickness. Cut off any leather that extends above the surface of the pad with a knife and use a rasp.

Joints and bushings are replaced or repaired.

Main causes of dimensional deviations:

– Incorrect measurement of the foot and lower leg.

Incorrect measurement of the foot, heel, ankle, sole, forefoot and cast;

– inconsistencies in the work of the measuring person,

Inconsistencies between the measuring device, the last adjuster and the adjuster; ¦ Incorrect selection and fitting of shoes based on customer measurements of foot and lower leg;

– Changes in foot measurements due to movement during the day.

Changes in foot measurements throughout the day. c

Ratio between foot and shoe pad length. The basic dimension of a solid base is the foot length L, its width in sections 0.07, OD 8, 0.68, 0.90 and the circumference in sloping sections 0.55, 0.68/0.72 of the foot length, calculated from Forefoot.

When determining the foot length L of the intermediate layers, the value P=5 is added to the foot length. The following designations are used: b = length of the insole; O = length of foot; P = allowance for all shoe types and sizes: 10 mm, except for summer shoes and shoes with oval insoles (moccasins), where the allowance is 5 mm; 5 = Metatarsal offset (insole): the most protruding part.

The allowance P can be increased depending on the shape of the forefoot. For modeling shoes with narrow toes, the allowance can be 15-25 mm. This is because the toe area can only be narrowed beyond the toe position.

Foot,

Hoof series. A series is a shoe of the same model, but in different sizes, interconnected by a certain pattern of changes in the basic parameters. In mass production, the shoes are made in a limited number of fittings: casual closed in three fittings with 0.72 / G.68L – 8 MMt model four fittings with 6 mm pitch. The distance between adjacent fittings is e.g. B. 4 mm for casual shoes and 3 mm for elegant shoes,

There are 12 fittings (from 1 to 12). In transitioning from one shaper to the next, one size fits all, the following information:

– Circumference in sections, mm 0.55L – & 0.72/0.68L – &.

– Sole width in sections, mm Q,18LH),7'0.8L -1.

Topography of the hoof. The lasts of shoes have three different surfaces: the upper (the so-called court), the bottom or insole (the so-called footbed), and the side surface (between the court and the footbed). *>

A distinction is also made between the inside and the outside of the insert. The upper, removable part of the footbed is called a wedge. The wedge is connected to the shoe by a spring fastener. The anvil of the shoe is divided into three parts: the back part - the heel, which rests on the heel; the middle part – the heel; the front part – the toe.

The widest front part of the shoe is called the chin, the furthest inward part is called the inner chin, and the furthest outward part is called the outer chin. The protruding front middle part of the insole is called the instep, and the uppermost part of the instep is called the ridge.

Insole numbering system. Each shoe should be marked with the following symbols: size, fullness number and shoe index. The shoe index consists of five or more characters, each of which identifies a specific feature of the shoe according to a specified classification.

The first digit of the index indicates the gender and age of shoes produced on a particular block: shoes - 0, running shoes - 1, toddlers - 2, children - 3, girls' school shoes - 4, girls - 5, school shoes for boys - b, boys ^ 7, women ~ 8t men - 9. ' ' ¦

The second digit of the indicator determines the type of footwear: closed shoes (boots, ankle boots, low shoes, sandals) *– 1; light shoes (sandals, sports shoes, slippers, travel shoes, stockings) – 2; open-toed summer shoes (shoes with open toes or heels) – 3; insulated shoes The third digit determines the height of the heel part of the shoe: The fourth digit (coefficient KJ) characterizes the shape of the toe area of the shoe and is determined by the ratio between the clearance a in the toe area and the width of the contact patch B of the shoe in section L , which is located at a distance equal to the length of the foot, calculated from the very tip of the heel, i.e. K – a/B. At K = 0.25 the nose is wide (number 1), at K = 0.251 . 0.549 – medium width (number 2), with K = over 0.55 – narrow (number 3).

The fifth and following numbers indicate the consecutive number of hooves in the respective group. For example, a hoof for warm weather shoes with a heel height of 20 mm and a medium forefoot width would have the index 94224, where the last number 4 stands for three already approved hooves in this group,

As an example, we decipher the hoof index 81233. The index numbers have the following meaning: 8 - women's, 1 - shoe, 2 - low heel (15-25 mm), 3 - narrow toe area, 3 - there are two already approved models in this group of Insoles.

The shoe index is supplemented with the letter M, and the shoe index for people with initial and significant foot deformities (including the elderly) is supplemented with the letter P.

conclusion

To conclude this ranking of shoe insoles, we would like to point out that shoe insoles are not just a functional and much-needed care accessory. They also help maintain the flawless appearance of the products and extend their lifespan. Meanwhile, since 2023, you can see the popularity of the models.

- Foam pillows – these pillows are often taken with you when traveling or on business trips;

- Molded Plastic Pads - These pads are suitable not only for travel but also for everyday use and long term storage. These pads have no special features, but are inexpensive.

- Wooden Washers – These are the best washers currently available, although they are more expensive than previous models. Among the washers made of this material you can find:

- inexpensive models with a springy heel;

- expensive counterparts that completely replicate the shoe, which affects performance.

And with the right skills you can even make them yourself at home; Step-by-step instructions with detailed video tutorials are easy to find on the Internet. However, it is up to you to decide which option is best and whether you choose to purchase or DIY a shoe mold. Purchasing a shoe shiner, no matter how much it costs, will be an effective help in caring for your shoes and boots for the season. According to buyers, you will not regret the money spent due to the long service life of the product.

How do you choose 'your' pair considering fit?

It is not very difficult to buy shoes that perfectly fit your individual parameters. Today's manufacturers use a wide range of lasts that allow you to choose the right footwear. The presence of a soft insole and special orthopedic insoles is of great importance when choosing. It is advisable to avoid shoes that are too narrow or too wide.

It is important to consider not only the height of the arch of the foot, its volume (fullness) and its length, but also your body composition. It is not advisable to wear shoes with thin, high stiletto heels. Shoes with a thick, stable heel with a smooth contour or a wedge heel are preferable. Taller women should not forego a small stiletto heel due to height problems. A few extra centimeters will not drastically change the overall picture, but will add a special charm and elegance to a woman's appearance.

Cedar Woodlore combination shoe spacers

Cedar Woodlore shoe spacers provide automatic artificial drying, absorb sweat, deodorize shoes and give them a natural, fresh scent. The Combination model combines a raised heel with a stretchy, split forefoot. These functional spacers are suitable for all shoe models. Steel mechanism.

- cedar wood, metal

Shoe spacer made of beech wood Dasco

The English company Dasco produces goods for people who value style and prestige. In its full-service stores that support this attitude, it offers practical spacers made of beech wood that wick away moisture and keep all types of women's and men's shoes in good shape. Quickly absorbs moisture and smoothes fine wrinkles in shoes.

- Beech, metal

- Repair of shoes

- Garment repair

- Handbag repair

- Repair of suitcases

- Renovation and painting of shoes, bags and jackets

- Watch repair

- Jewelry repair

- Repair and restoration of antiques

- glass repair

- Chemical cleaning

- Metal repairs

- Sharpen

- Handmade shoes

- rubber boots

- similar products

- Check order status

- Control and delivery

- Making hooves for shoes.

- Damaged insoles in shoes - what to do?.

- The insole of your shoes falls off.

- rim on the shoe.

- What does the insole of a child's shoe look like?.

- insoles for walking.

- Buy insoles for flat feet.

- insoles for shoes.